Secondly, you’ve probably noticed that all of my recent posts have had to do with natural flagstone, and I haven’t touched on some of the other materials available. That’s true, although not because we don’t work with other materials or that I’m not interested in sharing my knowledge. No, most of the recent posts have had to do with flagstone because in my experience flagstone offers the most in terms of needing to make decisions.

But I would be remiss in my series if I at least didn’t mention the topic of manmade paver stones.

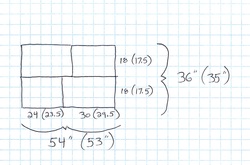

So how do they work? Pavers are designed to be installed in a dry-set technique. The process begins with approximately 8” to 10” excavation in the desired footprint, approximately 6” of compacted crushed gravel a bed of coarse leveling sand, with the pavers installed atop the sand bed. The edges are held in place with edge restraints to prevent the perimeter stones from migrating, and the interior stones are locked tightly together utilizing their inter-locking design.

In freeze-thaw climates like ours, pavers can make a great choice for hardscaping, as the installation allows some flexibility without the risk of cracking. They can also be lifted if need be to access underground utility lines or install

irrigation or wires if and when your needs change. Individual pavers are typically designed with a compressive strength of nearly 7000 psi or more depending on the manufacturer, nearly twice that of a standard concrete installation.

What that means for you is they will hold up without breaking, even in a driveway application with heavy vehicular traffic.

And if you spill that plate of greasy barbecue on your patio or your old truck slowly leaves an oil stain in your driveway, individual pavers can be lifted and replaced without having to spend hours trying to clean up a mess or spending big bucks demo’ing and replacing a large section.

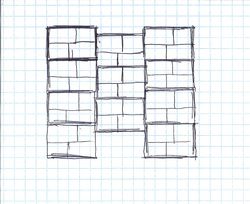

And from an installation point of view, what I really like about them is that they are all manufactured to precise specifications, meaning they fit together cleanly and quickly, with very little cutting or the need to accommodate various thickness of stone. What that means from a client perspective is cost-savings on labor.

As for overall installation costs, pavers are comparable to dryset clay brick, a dollar or two per square foot less than dryset flagstones and about $7-9 per square foot cheaper than wet-set flags. Of course, prices may vary slightly depending on the style of pavers you go with or the overall scope of each individual project, but in the grand scheme of things they are certainly an affordable option.

So there you go. Paver 101. Next week we’ll wrap up my hardscaping series with a quick overview of the options available. Until then, happy hardscaping!

RSS Feed

RSS Feed